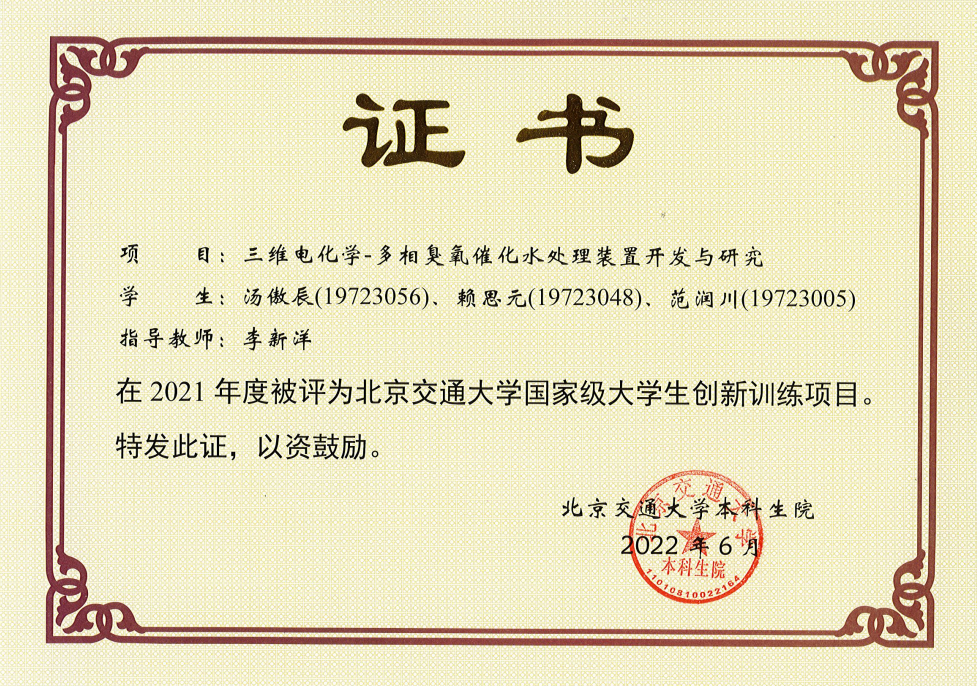

Applicants:Tang Aochen, Lai Siyuan, Fan Runchuan

Instructor:Li Xinyang

Project Introduction:

In recent years, ozone catalytic oxidation technology has been widely applied in the field of water treatment. However, the effectiveness of current technologies and equipment still needs improvement. Issues such as incomplete ozone decomposition, low ozone utilization efficiency, and waste caused by pure oxygen tail gas emissions are closely tied to resource efficiency. Addressing these problems and realizing the practical application of this technology holds significant importance for energy conservation and carbon emission reduction in today's society.

The overall system of this project integrates three independent yet interconnected subsystems: the pollutant concentration gradient system, the three-dimensional catalytic electrode system, and the pure oxygen recovery system. The complete physical device includes an oxygen generator, an ozone generation device, a three-stage sustainable electrochemical-multiphase ozone catalytic reaction water treatment device (forming a sewage concentration gradient, introducing a three-dimensional catalytic electrode, and enabling efficient conversion and degradation), a single-stage pure oxygen recovery device (utilizing residual pure oxygen to efficiently produce H2O2), a water supply pressurization device, and a three-way pipeline.

Compared to existing electrochemical-multiphase ozone catalytic processes, this project demonstrates significant advantages in pollutant removal efficiency and rate, while also addressing the imbalance between gas and water supply and demand. It resolves issues such as incomplete ozone decomposition, ineffective utilization of ozone tail gas, and waste caused by pure oxygen tail gas emissions, which are contrary to low-carbon emission reduction and tied to economic benefits. By achieving wastewater treatment while utilizing waste gas for economic benefits, the project achieves a synergistic effect of 1+1>2.

The ozone concentration at the inlet ranges between 70.50-71.20 mg/L, while only 3.04 mg/L remains at the outlet, achieving an ozone utilization rate of 95%. With a current of 300 mA applied to the reactor, the pollutant degradation rate reaches 99%, enabling the conversion of ozone and hydroxyl radicals and their efficient degradation of ozone-resistant pollutants. In terms of pollutant mineralization, a key indicator of the process's pollutant removal capability, the mineralization rate reaches 99%. For the above removal indicators, the corresponding energy consumption is approximately 0.18 kWh/g TOC (compared to traditional ozone technology's energy consumption of about 2.0 kWh/g TOC, approximately 1/10 of it). The concentration of H2O2 in the pure oxygen recovery device can reach 37.67 mg/L.